The OEM sensor buyer’s guide: Making sense of your options

This article is for design teams that integrate environmental sensors into their products. If you design test equipment, CEMS systems, laboratory instruments, IoT solutions, or industrial monitoring solutions, you face the same challenge: finding sensors that offer a balance between integration speed, data quality, and long-term maintainability.

The market offers thousands of options, but understanding how they actually divide, and recognizing which category fits your constraints, will save you from expensive mistakes and months of lost development time.

How the OEM sensor market actually divides

When you strip away marketing language and focus on what matters for integration, the market splits along two axes that determine your real costs: integration ownership and calibration control.

Integration ownership determines who’s responsible for turning raw signals into usable data. Calibration control determines who handles traceability, recertification, and long-term accuracy maintenance.

These create four distinct approaches, each with its own economics and trade-offs.

DIY sensor integration

Raw sensors from Sensirion, Bosch, or Honeywell give you bare components that output voltage or resistance changes. Your team owns everything: signal conditioning, ADC conversion, calibration curves, temperature compensation, drift correction, and communication protocols.

The advantage is total control. You optimize for exactly your use case—power consumption, sampling rates, accuracy ranges. Unit costs stay minimal, often under $20. You own your destiny.

The disadvantage is the hidden iceberg of work. That $20 sensor becomes a $50,000 engineering project. You need firmware engineers who understand signal processing. Your team maintains calibration procedures forever. Every sensor variation becomes your problem. Customer recalibration requests become your support tickets.

This approach wins when: You’re shipping 10,000+ units annually where every dollar of margin matters. You have embedded engineers with spare capacity. Your application needs specific optimizations no existing solution provides. You’re willing to own the entire measurement stack for the product’s lifetime. High-volume consumer products and automotive applications live here.

Smart sensor modules

Companies like Bosch Sensortec, Analog Devices, or Arduino-focused vendors package sensors with basic signal conditioning and digital interfaces. You get I2C readings instead of analog voltages, but still need to implement calibration logic and compensation algorithms.

The advantage is faster prototyping. A competent developer can get readings in days. The modules handle analog complexity while leaving you flexibility in digital implementation. Costs run $30-150 per module.

The disadvantage is living in no-man’s land. You still write calibration routines and handle edge cases, but now depend on someone else’s hardware design. You get neither the cost optimization of raw sensors nor the reliability guarantees of professional instruments. When customers need recertification, you’re still the one managing it.

This approach wins when: You’re building proof-of-concepts, educational products, or systems where environmental data is supplementary rather than core. When “good enough” data suffices and you won’t face audit requirements. Maker projects and internal tooling thrive here.

High-end measuring instruments

Fluke, Vaisala, Testo, and Novasina build instruments that output legally defensible measurements. You connect via Modbus, SDI-12, or proprietary protocols and receive data backed by decades of metrology expertise.

The advantage is transferred liability. These companies stake their reputation on every measurement. You get ISO 17025 calibration, regulatory documentation, and support from companies that have testified in court about their measurements. When something goes wrong, their lawyers handle it.

The disadvantage is cost and captivity. Expect $500-5000 per instrument. You’re locked into their ecosystem—their software, their annual calibration services, their feature roadmap. Integration means working around their design decisions. Customization means convincing their product team or paying for custom development.

This approach wins when: You operate in regulated industries where measurement disputes could mean lawsuits. Your customers specifically require name-brand instruments. You need someone else to own the liability. When failure costs millions or lives, when FDA or aerospace auditors will examine your data chain, this is often your only choice.

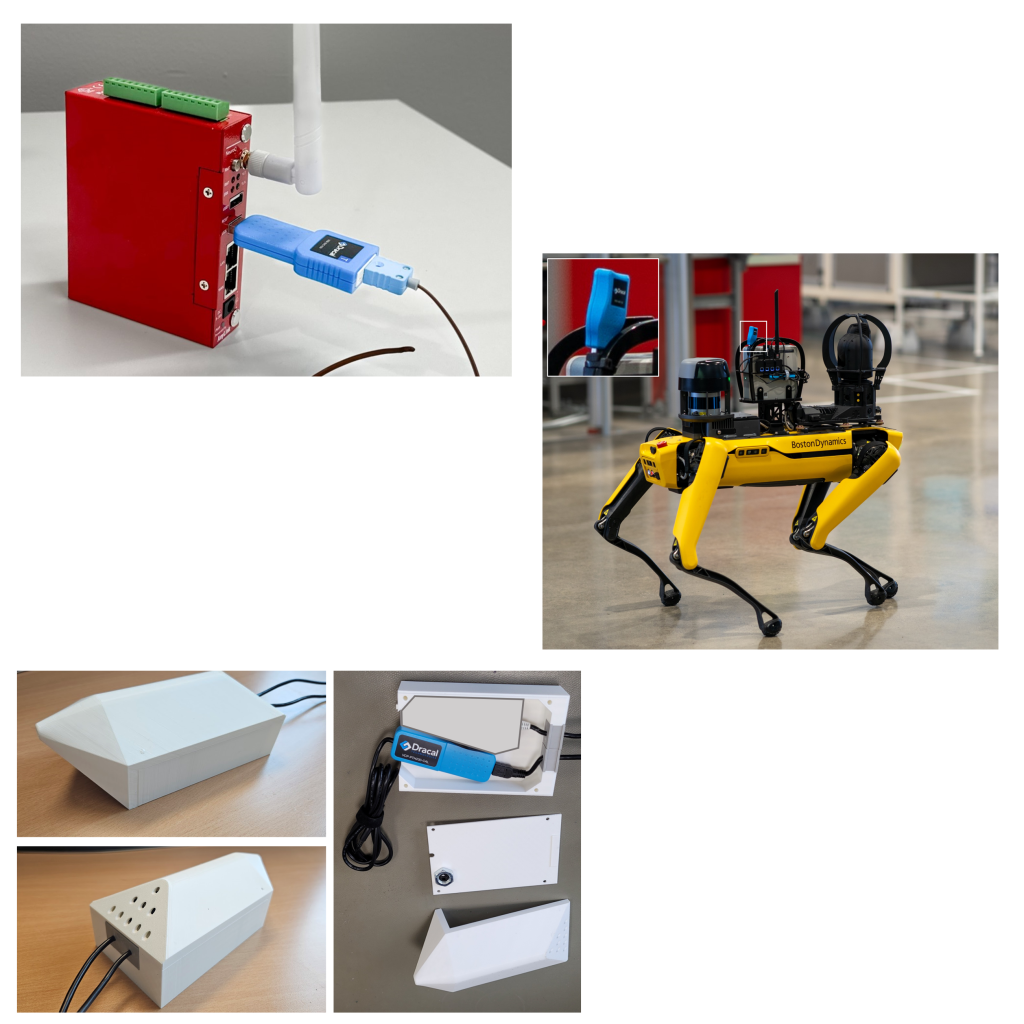

Modular precision sensors with ready-to-use data

This emerging category, where Dracal operates, provides instrument-grade measurements through standard interfaces with user-accessible calibration. You get USB-connected sensors that deliver ready-to-use data with calibration certificates and open tooling.

The advantage is development velocity without quality compromise. Integration takes hours using standard COM protocols. You get ISO 17025 traceable data without proprietary lock-in. Your customers can recalibrate independently using free tools, eliminating your support burden. No firmware development, no signal conditioning, no calibration algorithms to maintain. Costs typically run $200-500 per sensor.

The disadvantage is the USB-first design. If you need wireless, ultra-low power, or exotic bus protocols, this won’t fit. The per-unit cost sits above DIY solutions. You’re buying into an opinionated approach that prioritizes integration speed and user autonomy over infinite flexibility.

This approach wins when: You have urgent delivery timelines but can’t compromise on data quality. You operate in semi-regulated environments requiring traceability. Your support team is already overwhelmed. You want customers to handle their own recalibration. Your development team is small or focused on other differentiators. Laboratory equipment, environmental monitoring, industrial IoT, and testing systems find their sweet spot here.

Making the right choice for your constraints

There’s no universal “best” sensor strategy. There’s only the right fit for your specific constraints.

Start with your non-negotiables. If you testify in court about measurements, you need Fluke’s reputation. If you’re shipping next quarter to a regulated industry, you can’t afford six months of firmware development. If you’re building 50,000 units where every dollar matters, DIY might be your only path to profitability.

Then consider your hidden costs. That $20 sensor that needs three months of development isn’t really $20. Those Vaisala instruments that require annual factory calibration aren’t just expensive—they create recurring customer friction. Smart modules that still need calibration code mean your engineers become measurement experts instead of building your actual product.

Finally, think about support burden. Every calibration your team handles is a future support ticket. Every proprietary tool you adopt is a training cost. Every time customers can’t recalibrate independently, your team pays the price.

The expensive mistake isn’t picking the “wrong” category. It’s not recognizing which constraints actually matter until you’re three months into development, or worse, getting support tickets from deployed products.

For some teams, Dracal’s modular precision sensors provide exactly the balance needed—fast integration, quality data, and user autonomy. For others, only raw components or name-brand instruments make sense.

The key is knowing the difference before you write the first line of code.

Read our case studies

PRODUCTS YOU CAN TRUST

Approved by engineers, scientists and researchers around the world.

Thousands of companies trust our products worldwide:

Not sure if your project will benefit from Dracal’s solution?

Contact us, tell us about your project, and we’ll quickly determine if there’s a fit.

"*" indicates required fields

Always offered at no extra charge with our products!

EASY TO USE IN YOUR OWN SYSTEM

- Ready-to-use, accurate and robust real-time data flow

- Choose the interface that works best for you (CLI, virtual COM, REST API)

- Code samples available in 10+ programming languages (Python, C/C++, C#, Java, Node, .Net, etc.)

- Operates under Windows, Mac OS X and Linux

- Usable with LabView (CLI guide, Virtual COM guide)

- All tools packaged within one simple, free of charge, DracalView download

FREE DATA VISUALIZATION, LOGGING AND CALIBRATION SOFTWARE

- Get up-and-running in less than 3 minutes

- Operates under Windows, Mac OS X and Linux

- Real-time on-screen graphing and logging

- Log interval down to 0.5 second and configurable units (°C, °F, K…)

- Simultaneous use of unlimited Dracal sensors supported

- Simple user-calibration (products with the -CAL option)

- Connectivity with SensGate Wi-Fi/Ethernet gateway