4 practical tips for evaluating the durability of a data acquisition system (DAQ)

We believe that a manufacturer's reliability commitment encompasses three aspects: robustness, durability, and accuracy. Here, we will explore 4 aspects to evaluate the durability of a data acquisition system.

What does durability mean, and why is it important?

Durability refers to a product, system, or solution's ability to perform at its full potential over an extended period. Assessing durability during the selection process of a measurement system (instruments and/or DAQ) is crucial because opting for a durable solution minimizes:

- the resources required for hardware replacements

- software maintenance efforts

This allows allocating these valuable resources to higher-value tasks like product development, test implementation, and more.

How can one practically evaluate a solution's durability?

Here are 4 aspects to consider when evaluating the durability of a data acquisition solution.

1. Identify robustness elements

Evaluating the overall robustness of a complete solution involves considering mechanical, electronic, and software aspects. Robustness encompasses the measures taken by the manufacturer to ensure long-term functionality by eliminating potential weaknesses. These include component choices, electronic protections, and software communication tools.

Refer to this article to discover other elements to verify and assess a solution's level of robustness.

2. Evaluate natural drift and correction mechanisms

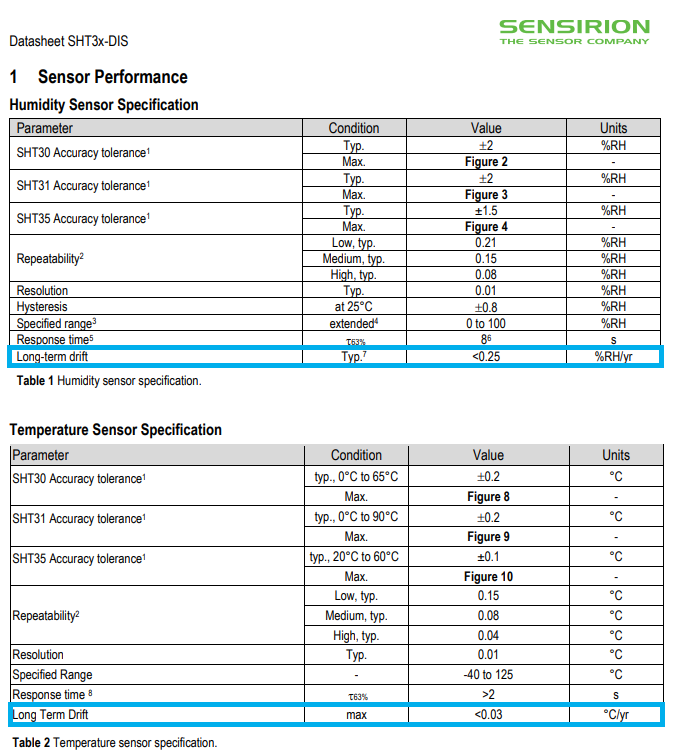

Any measuring instrument will experience natural drift in its readings, with varying rates based on quality, nature, and usage. A reference to natural drift is typically included in an instrument's datasheet.

Sensirion. Datasheet SHT3x-DIS Humidity and Temperature Sensor

https://sensirion.com/media/documents/213E6A3B/63A5A569/Datasheet_SHT3x_DIS.pdf

Check for the existence of mechanisms that allow adjusting the instrument's measurements to compensate for a natural drift. Such a mechanism will help maintain the instrument within its accuracy specifications for an extended period, significantly extending its lifespan.

3. Study backward compatibility assurance

This element applies to the entire system: instrumentation and data acquisition.

Backward compatibility assurance indicates whether your system, as implemented today, will still be supported in future years. Ideally, the manufacturer guarantees that future instruments and software will be compatible with the current ones.

In the absence of backward compatibility assurance, evaluate the solution's integration capabilities with other existing systems in the market to minimize the risk of implementing a solution that will no longer be supported in the future.

4. Assess company stability

Here, the manufacturer's years in business and their propensity to maintain their product and software offerings indicate the likelihood of sudden direction changes.

Of course, developing new products and solutions is a positive aspect as long as they coexist harmoniously with the products and systems already integrated by customers.

Working with a stable company reduces the risk of restarting the data integration process for new instruments and/or software solutions.

Note on planned obsolescence

By definition, planned obsolescence refers to the intentional implementation of mechanisms that limit the longevity of products and solutions solely to generate recurring revenue for the company. In 2023, any responsible entity should adopt a policy against this practice to value the precious resources of its users and the planet.