- 1. Introduction

- 2. Calibration Effects

- 3. Methodology

- 4. Supported Accuracy

- 5. Calibration Tools

- 6. Calibration in ISO/IEC 17025 certified laboratory

1. Introduction

First, a word about terminology. As defined in the International Vocabulary of Metrology, the mechanism we're talking about here is actually one of adjustment. However, as discussed in this article, we are using the "common" usage of the term "calibration", which includes not only the process of comparison with a more accurate instrument, but also that of correction of the values returned by the Dracal instrument.

The 3-point calibration by the user is supported by Dracal measuring instruments whose product code ends with "-CAL" (exé USB-PTH450-CAL). In a device equipped with this calibration mechanism, only the real channels are directly calibratable. Virtual channels, whose values are calculated from real channels, are however indirectly affected by the calibration applied to the channels from which they are calculated.

The user calibration mechanism supports calibration up to 3 points. However, the user is free to calibrate at only one or two points (or none at all!) if desired. By calibration point, we mean the association of a value measured by the instrument with its calibration value. The calibration function is polynomial and exact at calibration points. Calibration points are stored directly on the device, so that a calibrated device will remain calibrated regardless of the tool used to read its readings.

2. Calibration Effects

The purpose of calibration is to introduce a correction to the measurement read by a sensor, based on the measurement of a reference device called a "standard". There are several types of calibration functions, which we can divide into two categories: linear or non-linear. The calibration function supported by Dracal Technologies products is of polynomial type. This is equivalent to a linear calibration in the case of a 1-point or 2-point calibration. For a 3-point calibration, the polynomial calibration is non-linear and offers the advantage of being accurate at all three calibration points. In the following paragraphs, we illustrate the effect of polynomial calibration according to the number of points entered by the user. The different illustrations are based on a fictitious measurement curve in order to clearly visualize the various calibration effects.

Good to know! All calibration points are of equal importance. The order in which the points are entered has no effect on the calibration calculation.

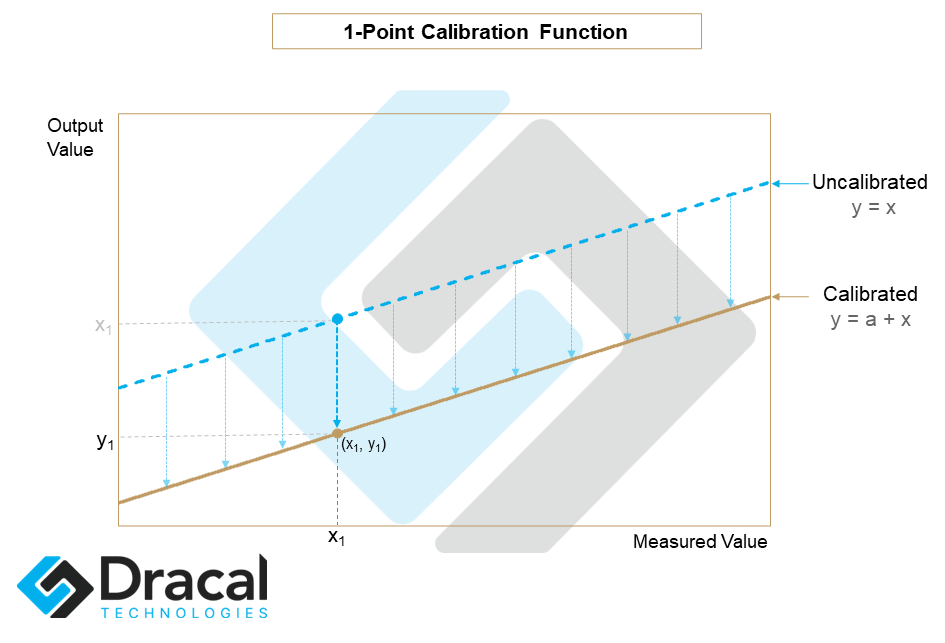

2.1. 1-Point Calibration

By one-point calibration, we mean the recording of a point (x1,y1 ) where x1 is the direct measurement of the sensor and y1 is the calibration value we wish to impose. A calibration point can therefore be schematically represented as a correspondence x1 -> y1. The effect of the calibration at one point is to apply a constant offset to all the measurements returned by the instrument. The calibration function for a 1-point calibration then has the following form: y = a+x. It is easily established that the value of this offset is: a = y1- x1. The calibration function for 1-point calibration is illustrated below:

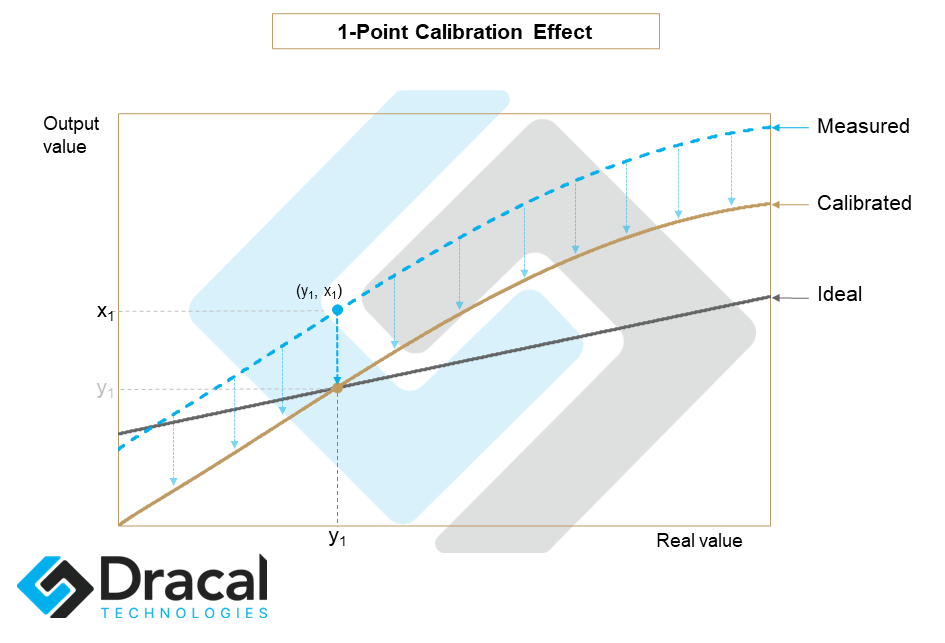

The effect of such a calibration on a measurement curve is illustrated below:

In a 1-point calibration, the point to be calibrated x1 should be approximately at the center of the user's intended measurement spectrum. For example, a user wishing to measure temperatures between 15 ℃ and 25 ℃ should not calibrate at the same point as a user wishing to measure temperatures between 20 ℃ and 70 ℃.

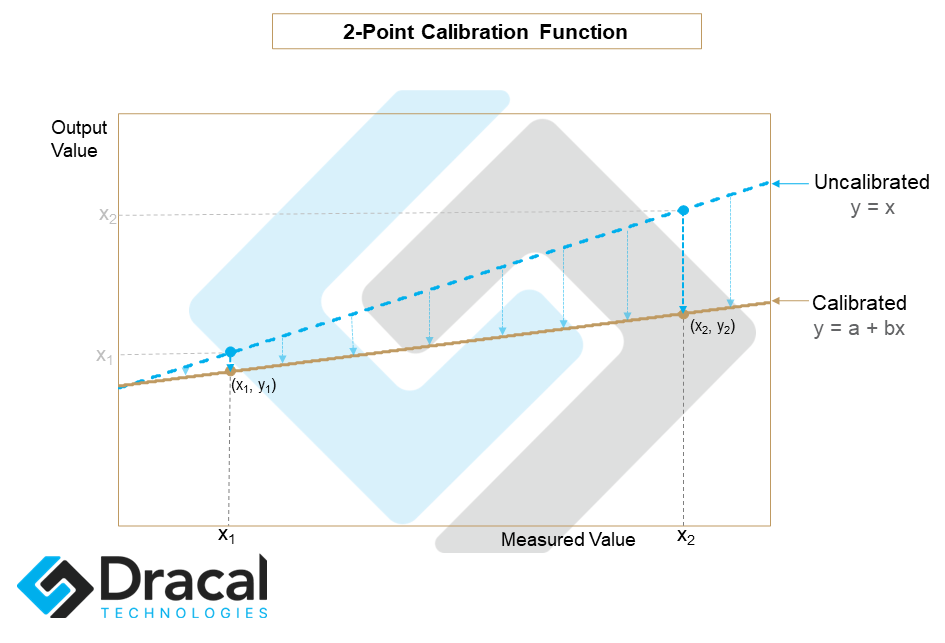

2.2. 2-Point Calibration

A two-point calibration is carried out by recording two correspondences: (x1,y1) and (x2,y2) and performs a linear correction. The calibration function then has the following form: y = a+bx This is illustrated in the following image:

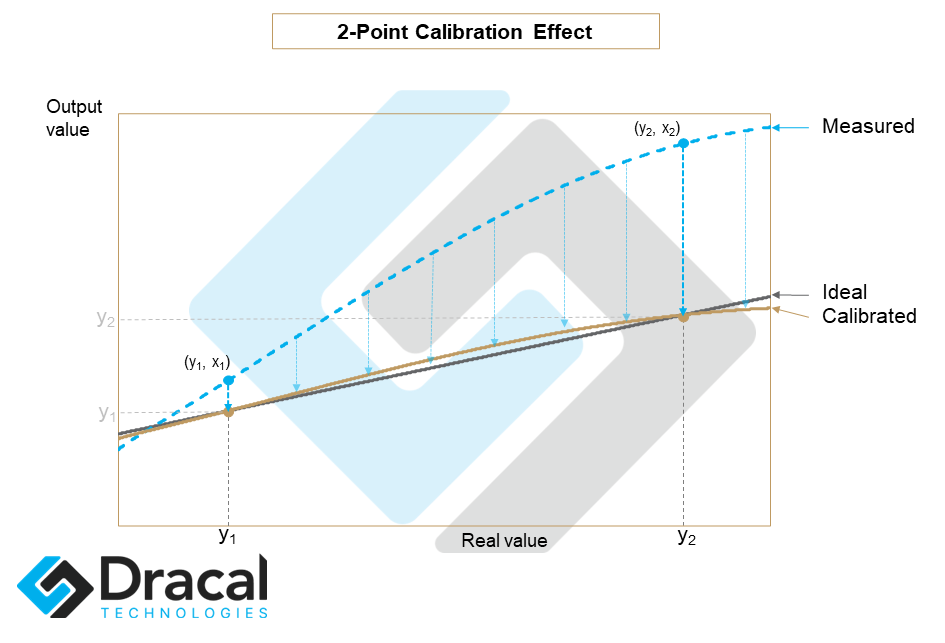

The effect of such a calibration on a measurement curve is illustrated below:

In a 2-point calibration, the points to be calibrated should be near the extremes of the measurement spectrum expected by the user.

2.3. 3-Point Calibration

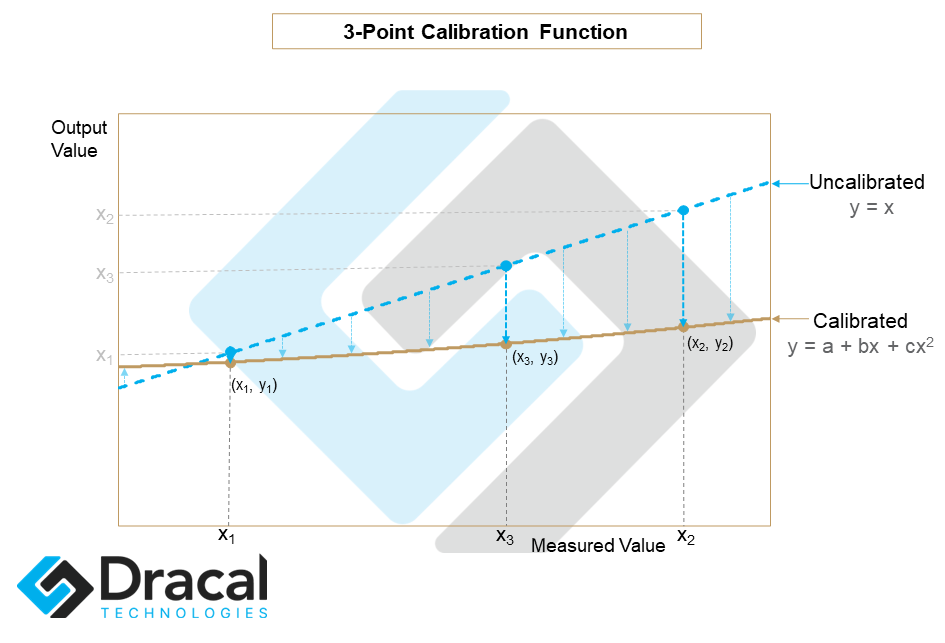

Finally, a 3-point calibration applies a degree 2 polynomial correction of the form y = a + bx + cx2. The coefficients a, b and c are calculated so that at calibration points x1, x2 and x3, the values returned by the calibration are exactly y1, y2 and y3 respectively. With this definition, the coefficients a, b and c are uniquely defined. The image below illustrates a possible 3-point calibration function:

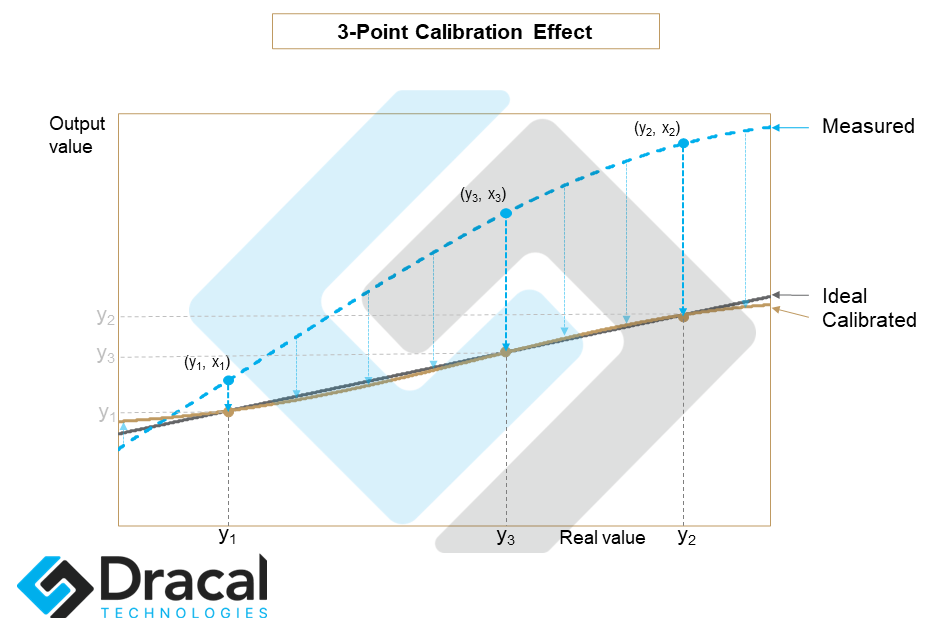

The effect of such a calibration on a measurement curve is illustrated below:

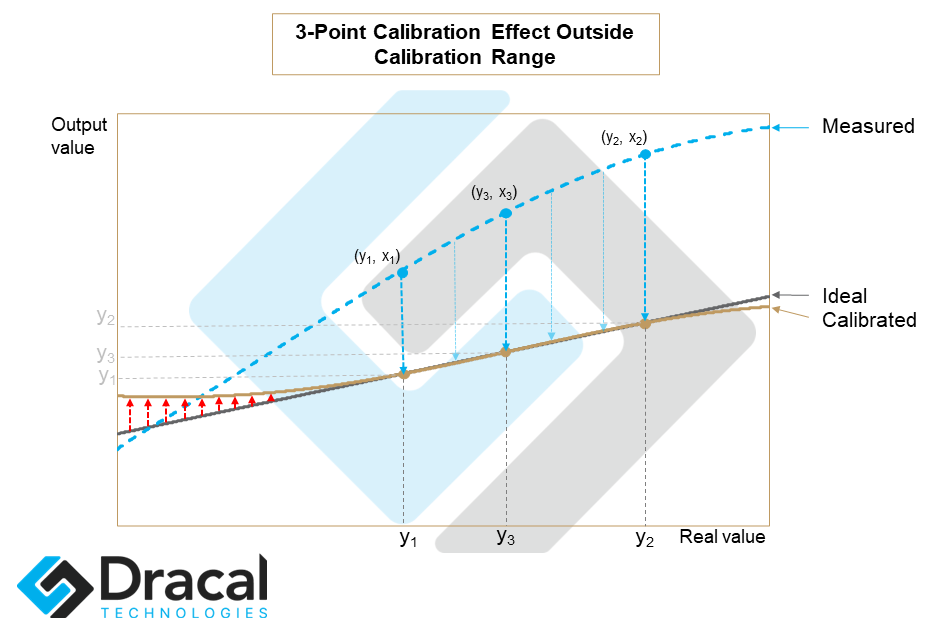

In a 3-point calibration, two of the points to be calibrated should be near the extremes of the user's predicted measurement spectrum, while the other should approximately lie in the center of the spectrum. The image below illustrates the importance of choosing calibration points so that they cover the expected operating range (not the theoretical range) of the instrument.

We can see from this example that although the calibration has considerably improved the accuracy of the measurement between the calibration points, it has deteriorated in the far left range away from the calibration points.

3. Methodology

The application of calibration is a double-edged sword. When carried out correctly, calibration offers a powerful and highly practical tool. However, when incorrectly programmed, calibration becomes a nuisance, potentially invalidating experimental results for a very long time - the time it takes to realize that an error has been made in its implementation.

Adopting the following basic principles will considerably reduce the risk of error, and ensure confident use of the calibration tool at your disposal.

We invite you to take a look at the 3-minute Practical Guide to successful calibration.

3.1. If possible, sample before calibrating

Before calibrating at a given point, take the time to compare the difference between the measured and theoretical values for a few points before and after the target measurement, in order to limit the risks of integrating noise errors in a calibration measurement.

3.2. Adapt the calibration points to the operating range of the instrument

Wherever possible, select calibration points so that they are centered and cover the planned operating range of the instrument.

3.3. Always define the calibration points from the raw measurements of the instrument

The risk here is to determine a calibration point when a calibration is already active. This can happen in 2 situations:

1) During multi-point calibration;

2) When recalibrating an instrument that already has adjustment points.

Before collecting data to determine your calibration points, it is essential to always check whether a calibration is already active, and if so, to deactivate it, if only for the time needed to take calibration measurements, as illustrated in our practical guide for calibration best practices with the tool.

4. Supported Accuracy

By definition, calibration is performed by adjustment calculations applied to the raw readings. The accuracy of the calibration calculations performed by Dracal products is accurate to 6 significant digits or more. That being said, it goes without saying that the accuracy of a calculation could not exceed the accuracy of the sensor itself. Therefore, when choosing the number of decimal places to be displayed, it should be based on the actual accuracy of the raw measurement and not on the number of display decimal places available.

5. Calibration Tools

Dracal Technologies provides you with two free tools to calibrate your Dracal devices supporting calibration: DracalView and dracal-usb-cal.

DracalView is our data acquisition and recording software. All features required for calibration have been implemented in DracalView v2.1.21 and later. Check out this short (3-minute) video tutorial to find out in an instant how easy it is to calibrate your device. If you'd like to go a little deeper into the methodology, our 3-minute "Best practices" guide will also be of great assistance.

dracal-usb-cal is a command-line tool developed specifically for terminal calibration. Consult the dracal-usb-cal documentation to familiarize yourself with the tool. Access to your instrument data via a command-line tool gives you the option of integrating calibration functionality into your own software.

6. Calibration in ISO/IEC 17025 certified laboratory

If your product is equipped with the user calibration mechanism, Dracal Technologies offers you the possibility to have your instrument calibrated (in a maximum of 3 points per real channel) and certified in an ISO/IEC 17025 certified laboratory. You will find on this page information about the traceability certificates issued by the laboratory. To determine if your device is eligible for ISO/IEC 17025 certified laboratory calibration, go to the "Ordering" page of your product and check if traceable certificates are available for it.