What Is the Traceability of an Instrument?

To answer the question posed in the title: "What is the traceability of an instrument?", we will see:

- What is an international measurement standard?

- How is a laboratory accredited by NIST or NRC?

- What is a traceability certificate?

- When is such a document needed?

What is an international measurement standard?

According to the International Vocabulary of Metrology (VIM), it is "a measurement standard recognized by signatories to an international agreement and intended to serve worldwide" (1). Good. Now, what is a measurement standard? It is the "realization of the definition of a given quantity, with stated quantity value and associated measurement uncertainty, used as a reference" (1).

Let's take a closer look at this definition.

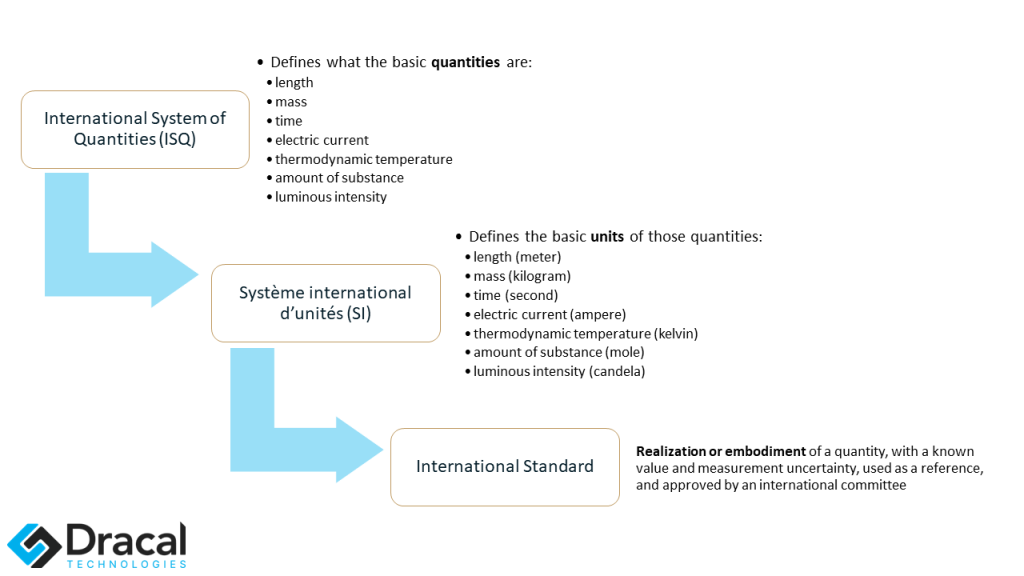

Realize a quantity by its definition. What is a quantity? The International System of Quantities (ISQ) has seven basic definitions: length, mass, time, electric current, thermodynamic temperature, quantity of matter, and light intensity.

The International System of Units (SI) comes into play here. The SI provides a base unit for each quantity in the ISQ. As of 2019, all SI units are defined according to physical constants (2). The last unit defined in this way was the kilogram. Therefore, creating a standard consists of using these SI definitions and making them into an entity that can be used as a reference with value and uncertainty.

In a schematic manner:

An international standard is, therefore, a reference entity recognized worldwide as being of "true" value.

How is a laboratory accredited by NIST or NRC?

The National Institute of Standards and Technology (NIST) in the United States and the National Research Council of Canada (NRC) are two federal agencies with the second type of standard: a national measurement standard. This reference entity is recognized for a given state or economy. It can generally be compared with the international measurement standard.

In Canada, laboratories are certified by the NRC Calibration Laboratory Assessment Service (CLAS) and accredited by the Standards Council of Canada (SCC) (3).

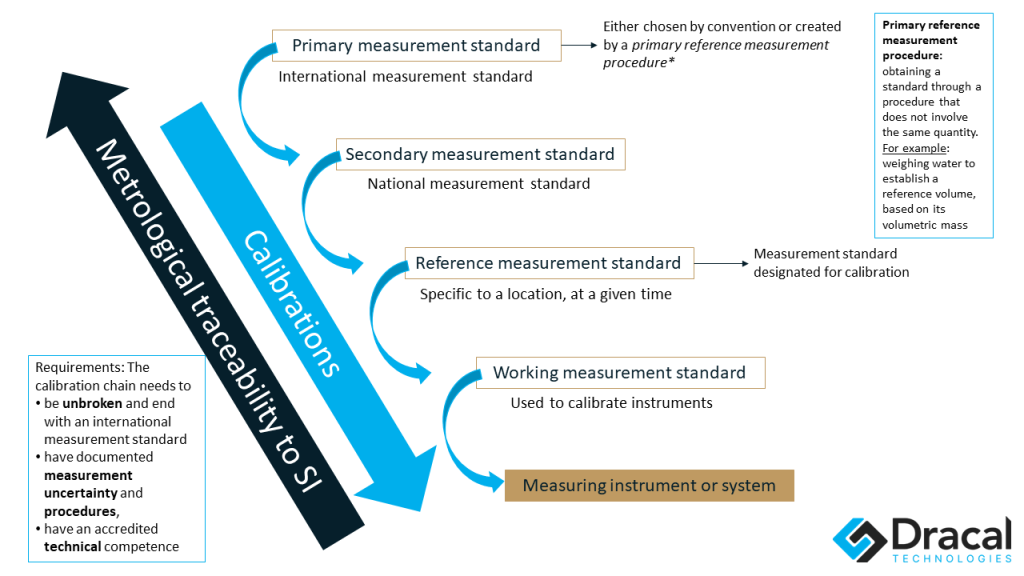

According to VIM, calibration is comparing X with a standard in terms of value and uncertainty of measurement.

For the laboratory to be accredited, it must demonstrate that its working measurement standards are derived from an unbroken chain of calibration from an international measurement standard, with documentation of the uncertainty of each calibration level. It must also have the personnel and equipment necessary to perform calibrations with high accuracy. Finally, it must pass the CLAS assessment for ISO/IEC 17025 accreditation.(4)

A Type I laboratory is used to calibrate standards.

A Type II laboratory calibrates measuring instruments from working measurement standards and produces a document establishing whether the equipment tested conforms to the manufacturer's standards.

What is a traceability certificate?

Metrological traceability is a property according to which an instrument's calibration has been done according to an uninterrupted and documented chain of calibrations, each contributing to the measurement uncertainty (1). This chain must be hierarchical with increasingly precise references. The documentation must include the unique identification number of the measurement standard used and the date its calibration was performed. When we speak of "traceability to the SI," the top of the hierarchy must be an international measurement standard.

Here is, schematically, the hierarchy necessary for certifying a measuring instrument.

Therefore, a certificate of metrological traceability to the SI, provided by a laboratory accredited by the Standards Council of Canada and the National Research Council of Canada (SCC-NRC), is based on working measurement standards. The laboratory must also follow strict procedures to provide the necessary accuracy when calibrating an instrument. The NIST operates similarly in the United States.

To obtain the certificate, the instrument user can choose calibration points. This allows an assurance of the accuracy of the instrument at targeted values. This choice should be made according to the final conditions of use of the instrument.

What is the difference between adjustment, calibration and traceability?

In common usage, calibration is correcting measurements to match expected values better. According to VIM, however, this definition corresponds to that of an adjustment.

Calibration, or comparing a measurement with a standard, is a prerequisite to adjustment. It is through calibration that a device can be adjusted to provide more accurate measurements at specific points.

A laboratory accredited to provide a traceability certificate must calibrate the device to verify its compliance. If the device has an adjustment function (sometimes called a calibration function), the laboratory can also adjust it.

Therefore, a traceability certificate does not guarantee that the device is adjusted to be more accurate. Instead, it is a certification that the measuring instrument conforms to the manufacturer's accuracy standards by comparing it to an unbroken chain of standards.

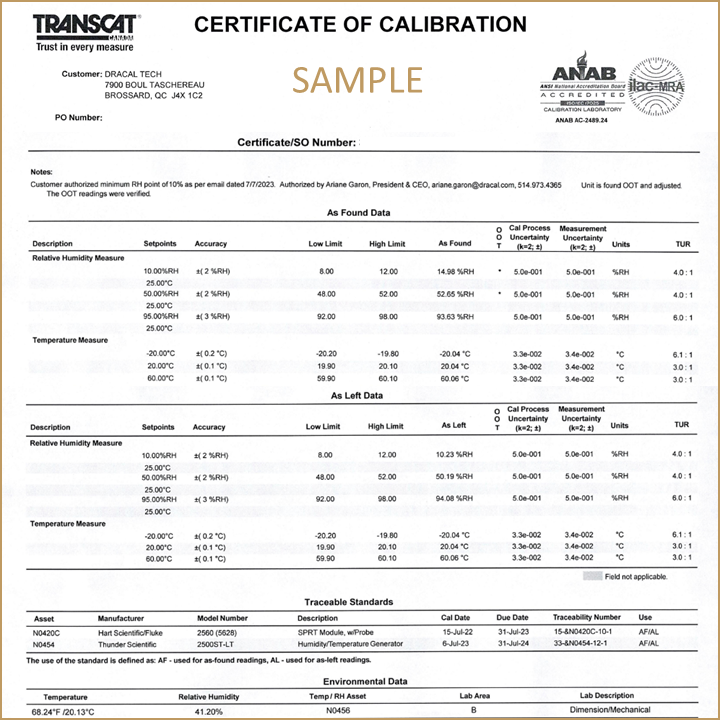

An example of a traceability certificate

So here's what a traceability certificate at CNRC (Canadian National Research Council) can look like. It was established for a USB temperature and humidity sensor (USB-TRH420-CAL). Temperature and relative humidity are the parameters used to calibrate this instrument.

As this measuring device is adjustable (the manufacturer calls it "calibratable"), during certification, the instrument was also adjusted to provide more accurate readings within a specific range (from -20 °C to 60 °C and 10%RH to 95%RH).

When is such a document needed?

The International Organization for Standardization (ISO) defines international standards as those approved by experts' committees. These standards are derived from the needs of a market and cover an extensive range. There are currently 24,495 standards. A consensus of experts and other committee members, such as consumers, establishes them. ISO Standards guarantee confidence in the quality of a product or process.

We briefly mentioned ISO/IEC 17025 above. This international standard "enables laboratories to demonstrate their competence and ability to produce valid results [... and facilitates] cooperation between laboratories and other organizations by ensuring better acceptance of results in different countries" (5). In metrology, this means that laboratories with this certification use reliable measuring instruments and procedures.

An NRC-accredited laboratory that passes the CLAS assessment for ISO/IEC 17025 certifies that the calibrated, SI-traceable measuring instrument will produce internationally recognized valid results. The same is true for NIST-accredited laboratories.

In some industries, this validity must be demonstrated. A traceability certificate assures the purchaser that the measuring instrument complies with this standard.

To conclude

We hope to have clarified some basic questions about the traceability certificate, calibration, adjustment and the various international standards. If you have any questions or comments, we will be happy to answer them!

References

- BIPM, IEC, IFCC, ILAC, ISO, IUPAC, IUPAP, and OIML. International vocabulary of metrology | Basic and general concepts and associated terms (VIM). Joint Committee for Guides in Metrology, JCGM 200:2012. (3rd edition). URL: https://www.bipm.org/documents/20126/2071204/JCGM_200_2012.pdf/f0e1ad45-d337-bbeb-53a6-15fe649d0ff1.

- BIPM. Brochure sur le Système international d’unités (SI) v.1.08 (9e édition) ISBN: 978-92-822-2272-0

- Gouvernement du Canada (2022). Notes supplémentaires - Service d’évaluation de laboratoires d’étalonnage. [online] Conseil national de recherches du Canada. Available at: https://nrc.canada.ca/fr/certifications-evaluations-normes/service-devaluation-laboratoires-detalonnage/notes-supplementaires [Accessed 22 Sep. 2022].

- Gouvernement du Canada (2019). Obtenir la certification CLAS. [online] Conseil national de recherches du Canada. Available at: https://nrc.canada.ca/fr/certifications-evaluations-normes/service-devaluation-laboratoires-detalonnage/obtenir-certification-clas-1-commencer [Accessed 22 Sep. 2022].

- ISO. (2017). ISO/IEC 17025 - Exigences générales concernant la compétence des laboratoires d’étalonnages et d’essais. [online] Available at: https://www.iso.org/fr/publication/PUB100424.html [Accessed 26 Sep. 2022].